GALVANIZATION AND LINES FOR SURFACE PREPARATION

TECHNOLOGY, PRODUCTION LINES AND EQUIPMENT FOR GALVANIZATION, SURFACE PROTECTION OF MATERIALS AND CHEMICAL PREPARATION.

TEHNIKUM is a company that has a highly competent team with decades of experience in the field of surface protection and galvanization, "hot dip galvanizing", chemical application of surface protection, electrostatic application of powder, metallization, etc.

Our technologists have gained their first great experiences in galvanizing "Prva Petoletka Trstenik", which is known for making parts for airplanes and other demanding industries. They were also trained in the world's leading companies for the production of aircraft BOING, TUPOLJEV...

Our licensed engineers have reliable and productive solutions ranging from production planning, technology provision, design, manufacturing, assembly and commissioning of production lines and factory plants.

Our solutions put the quality of surface protection, safety, and environmental protection on the first place.

We design and construct the most modern plants, systems and equipment for the surface protection industry, according to your requirements, using innovative ideas and vast experience, in order to provide optimal techno-economic solutions.

WE ARE EXPERTS IN ALL SURFACE PROTECTION TECHNOLOGIES

- Electrolytic galvanizing

- “Hot” galvanizing

- Anodic oxidation of aluminum (so-called anodizing)

- Decorative chromium plating

- “Hard” chromium plating

- Electropolishing

- Passivation

- Phorosphitization

- Phosphating

- Chemical nickel

- "AD coating"

- Gilding (application of gold coating)

- Electrostatic powder coating – plasticization

- Paints

- Metallization (application of molten metal) and other…

- Surface preparation of parts: chemical degreasing, electrolytic degreasing, ultrasonic degreasing

- Including following technologies and processes: wastewater treatment, water treatment (demi water), extraction and purification of polluted air, through production to installation and commissioning of production lines and factory plants.

WE PROVIDE OUR CUSTOMERS COMPLETE SUPPORT

- Technological solutions and definition of technology according to customer requirements

- Project documentation (conceptual design, projects, obtaining necessary permits and approvals from competent authorities)

- Construction and manufacture of equipment and complete plants

- Automation of production lines "automatic transport systems" tools "And" drums "along the line, automatic solution correction, etc.)

- Ventilation and suction of chemical vapors

- Production of scrubbers for purification of toxic fumes

- Wastewater treatment systems

- Purification of chemical concentrates and dehydration of generated sludge

- Service team for monitoring and maintenance of plants

Our competent teams work closely together in order to ensure the various components of the system work seamlessly with each other, from planning to commissioning, through high environmental standards, resource saving plans and energy efficient systems, proving that environmental protection is our priority.

DESIGN, PREPARATION OF PROJECT DOCUMENTATION AND OBTAINING THE NECESSARY PERMITS AND APPROVALS of the competent authorities from location conditions, construction permits, use permits, water permits, etc.

- Development of Preliminary design

- Projects for building permit

- Project for construction

- Project of fire protection

- Projects of the constructed facility

- Study on the assessment of the impact of the project on the environment, etc.

Reference list of projects for galvanizing equipment, see...

MANUFACTURE OF COMPLETE FACTORY GALVANIC PLANTS, EQUIPMENT AND LINES FOR SURFACE PROTECTION

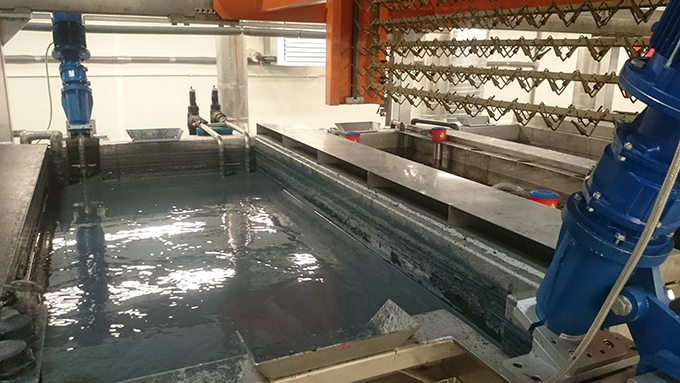

SYSTEM OF GALVANIC BATHTUBS

Depending on the technological requirements, we make galvanic bathtubs from HDPP, HDPE, PVC, stainless steel, etc., equipped with the necessary systems for temperature regulation, solution mixing system, as well as maintaining the set solution concentrations, frequent movement of parts - cathode shift, etc.

ELECTRO-COMMAND CABINETS FOR AUTOMATIC PLANT CONTROL

- Automation of complete plants

- Full automation of transport of parts along the production line

- Automatic transfer of parts from one technological operation to another

DRYERS AND CENTRIFUES FOR DRYING PARTS AFTER GALVANIC PROTECTION

They are used for drying larger parts that are made with tools. We install anti-corrosion materials (acid-resistant stainless steel), thermal insulation and heaters of appropriate power and fans for air circulation.

TRANSPORT SYSTEMS FOR MOTION OF BATCHES AND GALVANIC DRUMS LENGTH OF THE PRODUCTION LINE

Fully automatic or semi-automatic, with portal and crane type lift, conveyors, etc.

TITANIUM BASKETS FOR ANODES

ANODE BAGS

They serve to protect the anodes - they protect the anode from "stickers", they are made of PP or PE. They are placed on anodes made of zinc, nickel, copper that are in the tub and "protect" the anode from pollution. We make them of all dimensions according to the customer's request.

GALVANIC DRUMS

Galvanic drums are made of HDPP, of different capacities, equipped with a rotary drive, and other necessary equipment,

RECTIFIERS - DC TRANSFORMERS, with air cooling, water cooling, and oil cooling, with power and voltage regulation and automatic pole change.

FILTER UNITS FOR FILTERING SOLUTIONS IN WORKING TUBS.

Reference list of galvanizing equipment projects, see...

VENTILATION SYSTEMS FOR EXHAUST AND PURIFICATION OF HARMFUL GASES AND VAPORS ABOVE GALVANIC BATHTUBS

We design, manufacture and install ventilation systems (suction) over galvanic baths with air purification devices: scrubbers, filters and other activated carbon.

- Extractors, extractor hoods and ventilation ducts

- Fans of different capacities. Materials: HDPP, stainless steel, carbon steel with anticorrosive protection

- Drop separators

- Scrubbers for purification of polluted vapors from galvanic baths, etc.

Reference list of completed projects of plants and equipment in galvanization, see...

OPTIMIZATION AND IMPROVEMENT OF TECHNOLOGICAL PROCESSES

Various technical solutions and improvements in galvanization processes.

WASTEWATER TREATMENT AND CONCENTRATES FROM GALAVNIZATIONS

DESIGN, PRODUCTION AND INSTALLATION OF SYSTEMS - COMPLETE PLANTS AND EQUIPMENT FOR WASTEWATER TREATMENT FROM ALL TYPES OF GALVANIZATION PROCESS AND SURFACE PROTECTION

- Neutralization devices

- Flocculation devices

- Sedimentation tanks made of PP, PE, carbon steel with anti-corrosion protection, stainless steel, etc.

- Design and installation of automatic control systems: level meters, flow meters, dosing pumps, pH meters, probes

- Activated carbon filters

- Systems for water filtration and return to the process-regeneration. Columns with ion exchange resins

- Aerators, etc.

SLUDGE DEHYDRATION PRESS FILTER

Natalog in the process of neutralization and precipitation.

All our devices and systems meet the valid European and domestic standards.

News

DAF DEVICES

DAF (Dissolved Air Flotation) device is used for separation of dispersed and suspended particles from wastewater. Flotation is a mechanical separation proccess based on making supersaturated air solution in wastewater, meaning that micro bubbles make contact and connect with suspended substances and enable them to reach the surface and float.The air is being dispersed from the bottom of the pool, t it “collects” particles on it’s way up and pushes them to the surface. Coagulant neutralizes the electrostatic load of colloid particles and enables their agglomeration into floccules. Polyelectrolyte connects the neutralized particles into even bigger floccules. Piping saturator has a unique construction and enables air bubbles with dimensions 10-70 micrometers, what provides an extraordinary efficiency. AREAS OF APPLICATION AND MAIN APPLICATIONS Milk industry, ice cream production, juice production, alcoholic beverages production, breweries, fish and meat processing, fruit and vegetables processing, drinking water, etc. Plastic recycling, chemical industry, oil and gas, textile industry, leather industry, laundry services, package washing etc. Advantages of our DAF Systems: - Very high level of reduction of pollution parameters Suspended substances Reduction rate from 90-99% Oils and fats Reduction rate trom 90-99% BPK5 Reduction rate from 70=80% HPK Reducstion rate from 70-80% - Comprehensive and efficient solution which provides high stability and efficient removing of dirt. Reliable method for refining of technological wastewater. - Simple installations provide compact equipment set and saves space. - Major savings because the system construction and technological parameters ensure small consumption of energy, air and chemicals. - Very stable functioning of coagulation, neutralization and flocculation systems. - Law level of turbulences, there is no re-retraction of floating sediments. - We have available a developed digital services package which provides follow-up and optimization of the DAF system long-distance working and remote controllie of thesystems. - Instead of classical lamellas, we use special “U” profiles which provide: Separated flowi of wastewater and clean water Equal distribution of wastewater flow and sectors load, decreasing the turbulence There is no obstruction of flow of flotants Flow leaders secure less consumption of polymers DAF is a device made of stainless steel We can deliver complete systems or rebuild and upgrade existing DAF devices.

Read more

TECHNOLOGICAL TREATMENT PLANT FROM BATTERY PRODUCTION AND RECYCLING WASTEWATER

Type of wastewater: technological wastewater from battery production and recycling Capacity: 700 m³/day, 29 m³/h Table 1: Types of wastewaters and damaging and dangerous substances generated during the production process Types of wastewater Origin Existing hazardous and dangerous matters Alkaline rinsing water Workspace and streets cleaning Lead and dust Sour rinsing water with high concentration Paste mixer and shepherd machine washing Pb, PbO2, PbSO4 Neutral concentrates Wet Ventures - scrubbers Pb, Sn, Sb, hydroxides Water from battery formulation Charging battery with acid Sulfuric acid Water from battery recycling Cutting and emptying of battery Sulfuric acid, Pb, PbO2, PbSO4 Outgoing water quality Purified wastewater from the treatment plant should satisfy the following limit values for discharing into the land waters (in this case a small river). Limit values are extremely low for some hard metals, which are contained in these wastewaters, such as: Cadmium – 0,1 mg/l Lead – 0,5 mg/l Iron – 2 mg/l Sulfates – 250 mg/l Suspended substances – 35 mg/l BPK5 – 25 mg/l HPK – 125 mg/l, etc. The investor’s request was to deliver a technological solution – Technology for wastewater processing through the project: machine, electro and measuring regulating equipment, electro-commanding cabinet with PLC and software, launching and a guarantee that the required parameters will be inside the limit values. Plant working regime: Continually (moze I : non-stop), 24h/7 daysOV generated during he production process are being treated trough three lines: Water line Dirt line Preparation and chemicals dosing line These technologies are being established on the water line: Egalisation Neutralisation Neutralisation II and removing of sulfates Coagulation Flocculation Sedimentation Clarification of sedimented water Final control These technologies are being established on the preparation and chemicals dosing line: Preparing a dosing solution Dosing the solution The system is completely automatized, with support of electro- commanding cabinet with SIEMENS PLC, software and measuring regulation equipment. After the equipment is delivered and the system is launched, chemical analysis of the purified OV have been done in an accredited lab. Those analysis showed that all parameters were inside the limit values.

Read more

MEMBRANE FILTER PRESSES

Filter plates at Mebrane filter press are equipped with membranes that enable additional "squeezing" -dehydration of the filter cake. Increasing the filling pressure ensures precompression and drainage of the filter cake in the chamber. When the filling pressure reaches a predetermined value (approximately 6-8 bar), the filter cake is additionally exposed to the membrane pressure, and additionally "squeezed". Elastic membranes, which can be made of polypropylene (PP) and synthetic rubber (NBR, EPDM), use compressed air to press the filter cake over the entire surface of the chambers. Additional compression thus expels free water through the filter cloth. ADVANTAGES OF MEMBRANE FILTER PRESSES: • More economical filtration due to high degree of drainage and shorter cycle time Maximum flexibility for expansion and automation possibilities Extended pump life in the case of abrasive media, due to low supply pressure CASE STUDY: Delivery of membrane filter press with the dimensions of plates 1000x 1000 mm, 36 plates, volume 770 liters, for filtering the solution of lead "paste" in the process of battery recycling. Investor "TAB MAK". The press is equipped with: membrane plates with EPDM membrane, system for automatic opening of plates, "Squezing" system for additional dehydration of filter cakes, "drip tray" system. Degree of dehydration of filter cakes: 80-90% dry matter..

Read more