DAF (Dissolved Air Flotation) device is used for separation of dispersed and suspended particles from wastewater.

Flotation is a mechanical separation proccess based on making supersaturated air solution in wastewater, meaning that micro bubbles make contact and connect with suspended substancesand enable them to reach the surface and float.

Purified wastewater from the treatment plant should satisfy the following limit values for discharing into the land waters (in this case a small river). Limit values are extremely low for some hard metals, which are contained in these wastewaters

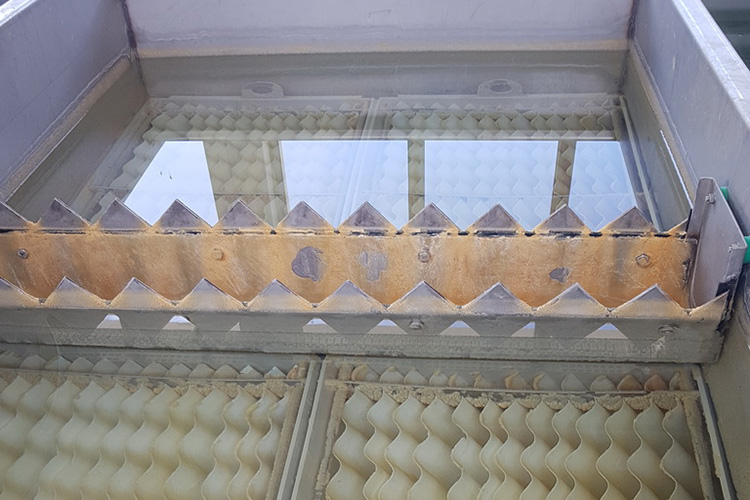

Filter plates at the Membrane filter press are equipped with membranes that enable additional "squeezing" -dehydration of the filter cake. Increasing the filling pressure ensures precompression and drainage of the filter cake in the chamber.

Due to the constant requirements to achieve the most efficient clarification (separation) by chemical pre-treatment and sedimentation, we have developed a precipitator with special package inserts. The basic characteristic of these precipitators is the high efficiency of deposition-clarification per unit of its volume.

MBR (Membrane bioreactor) technology is based on the removal of pollution by a combination of microorganisms and microfiltration, which eliminates the need for the existence of a secondary precipitator. In addition, the MBR forms very efficient removal of organic pollution, which is accompanied by a constant quality of wastewater or an uniform quality of wastewater in relation to larger fluctuations in the quality of incoming water.

We have successfully finished delivery, installation and launching of membrane filter press which filtrates lead from the acid (lead paste) in the battery recyclation proccess, for the TAB MAK company, specialized in production of batteries.

The filter Press is fully automatised and equipped with the membrane filter plates, what allows for a very efficient dehydration, “squeezing”, of the filter “cake”.